Single magnetite beneficiationThe composition of iron ore of a single type of magnetite is simple, the proportion of magnetite in iron minerals is very large, and the gangue minerals are mostly quartz and silicate minerals. According to production practice research, weak magnetic separation methods are often used for separation. , In large and medium-sized magnetic separation plants, the ore is demagnetized and entered into the crushing and screening workshop to be crushed to a qualified particle size, and then sent to the grinding workshop for grinding operations.

If the particle size of the ore after grinding is greater than 0.2 mm, a one-stage grinding and magnetic separation process is used; if it is less than 0.2 mm, a two-stage grinding and magnetic separation process is used. In order to improve the recovery rate of iron ore as much as possible, the qualified tailings can be scavenged for further recovery. In areas lacking water resources, dry ball mills and magnetic separators can be used for grinding and magnetic separation operations.

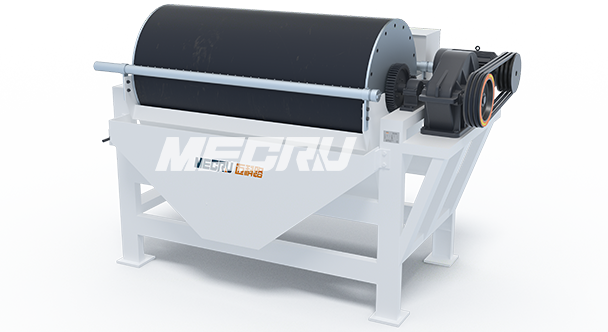

Because magnetite is easily depleted under weathering, such ores are generally sorted by dry magnetic separator to remove some gangue minerals, and then subjected to grinding and magnetic separation to obtain concentrate.

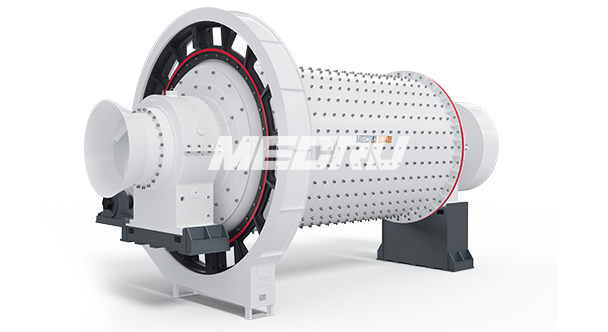

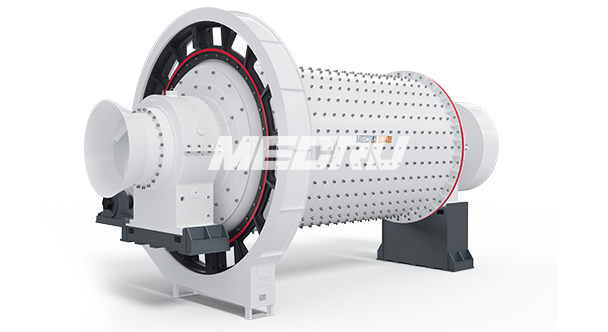

ball mills

ball mills

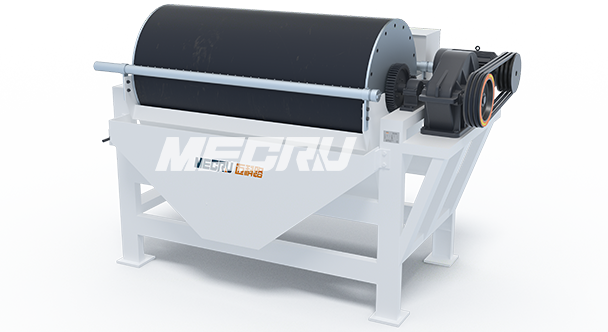

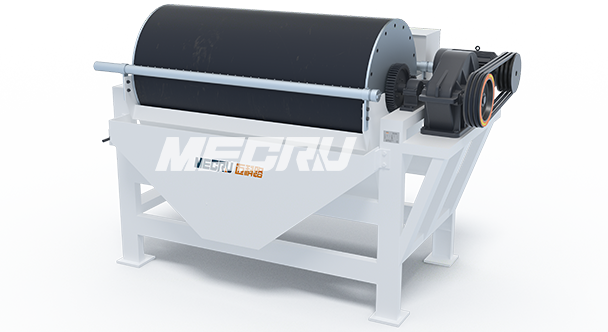

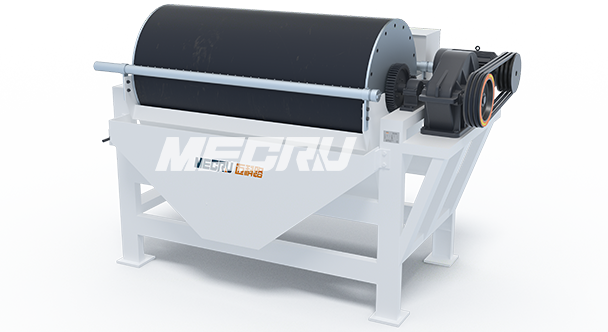

magnetic separators

magnetic separators

Polymetallic magnetite beneficiationThe magnetite in the polymetallic magnetite is sulfide magnetite, and the gangue mineral contains silicate or carbonate, as well as cobalt pyrite, chalcopyrite and apatite. Such ore generally adopts the combined process of weak magnetic separation and flotation to recover iron and sulfur respectively.

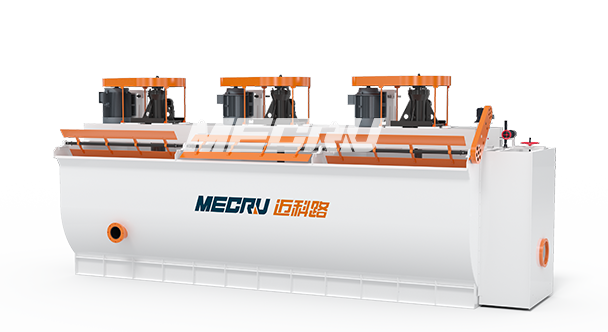

Process flow: The ore is fed into the magnetic separator for weak magnetic separation to obtain magnetite concentrate and weak magnetic separation tailings, and the tailings enter the flotation process to obtain iron and sulfur.

magnetic separators

magnetic separators

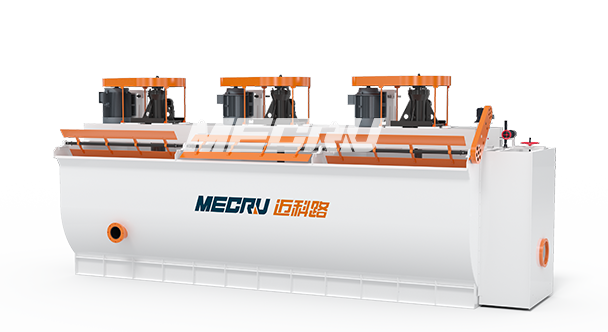

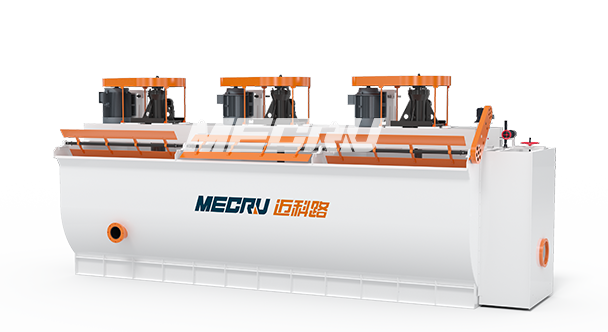

flotation machine

flotation machine

Single weak magnetite beneficiationCommon weakly magnetic iron ores include hematite, siderite, and limonite. There are two commonly used methods, depending on the type of mineral and the particle size of the embedded distribution:

(1) Roasting

Roasting magnets are used to sort weakly magnetic iron ore with complex mineral composition and other sorting methods are not effective.

The common process flow in actual production is: raw ore is fed into the shaft furnace for roasting and magnetization, and after magnetization, it is fed into the magnetic separator for magnetic separation.

(2) Flotation, gravity separation, strong magnetic separation or their combined process

Flotation multi-selects fine-grained to particulate magnetic iron ore (grain size < 0.02 mm).

Gravity separation and magnetic separation are mainly used to separate coarse-grained and medium-grained weak magnetic iron ore (20~2 mm). During gravity separation, the gravity separation of coarse-grained and very coarse-grained (>20 mm) ores is usually carried out with heavy media or jigging; reselection method.

In magnetic separation, dry magnetic separators are commonly used for strong magnetic separation of coarse and medium-grained ores; wet strong magnetic separators are commonly used for fine-grained ores. Since the concentrate obtained by a single beneficiation method is not of high grade, a combined process is often used:

Combination of flotation and magnetic separation: the magnetite-hematite ore with qualified particle size is fed into the magnetic separator for weak magnetic separation to obtain strong magnetic iron concentrate and weak magnetic separation tailings, and the tailings are fed into the magnetic separator for Strong magnetic separation, strong magnetic separation tailings and concentrate are obtained, and the concentrate is fed into the flotation machine for flotation to obtain flotation iron concentrate tailings.

Combined gravity separation and magnetic separation: Similar to the combined process of flotation and magnetic separation, only flotation is replaced by gravity separation, and the products are gravity separation concentrate and tailings. Both of these combined methods can improve concentrate grades.

Mineral processing of polymetallic weak magnetiteSuch ores generally recover iron ore by gravity separation, flotation, strong magnetic separation or combined process, and recover phosphorus or sulfide by flotation.

The above are mainly the common sorting methods and technological processes of strong magnetic and weak magnetic iron ore. The composition of natural iron ore is often not so simple, so in actual production, it is necessary to do mineral processing experiments to clarify the mineral composition, and use a single sorting method or a combined sorting method according to the corresponding mineral properties. In this way, the beneficiation effect can be improved.

Magnetic Separator

Magnetic Separator

SF Square Flotation Cell

SF Square Flotation Cell

+86 139 3711 5575

+86 139 3711 5575 mecru@mecru.com

mecru@mecru.com 8613937115575(Whatsapp/Wechat)

8613937115575(Whatsapp/Wechat) No. 67, Taojia Road, Guangwu Town, Xingyang City, Zhengzhou city, Henan Province, China

No. 67, Taojia Road, Guangwu Town, Xingyang City, Zhengzhou city, Henan Province, China