-

Mobile crushing plant

Tracked Jaw Crusher Tracked Impact Crusher Tracked Cone Crusher Tyre Jaw Crusher Tyre Cone Crusher Tracked Screening Plant Tracked Heavy Screening Plant Multi-Combination Tyre Plant

-

Stationary crushing plant

Vibrating Feeder Gyratory Crusher C Series Jaw Crusher C Series Impact Crusher HPG Multi-cylinder Hydraulic Cone Crusher CG Single-cylinder Hydraulic Cone Crusher VSI Sand Making Machine Inclined Vibrating Screen Bucket Type Sand Washing Machine

-

Mineral processing plant

Ball Mill Cement ball mill YF Round Flotation Cell C Column Flotation Cell SF Square Flotation Cell Magnetic Separator Spiral Classifier Spiral Chute Shaking Table Trommel Screen High Frequency Vibrating Screen Agitating leaching tank Wet Pan Mill Centrifugal Gold Concentrator Agitation Leaching (SX) Solvent Extraction (EW) Electrowinning

-

Hydrometallurgical plant

EPC - Gold Cyanidation EPC - Copper Ore EPC - Copper-cobalt Ore

-

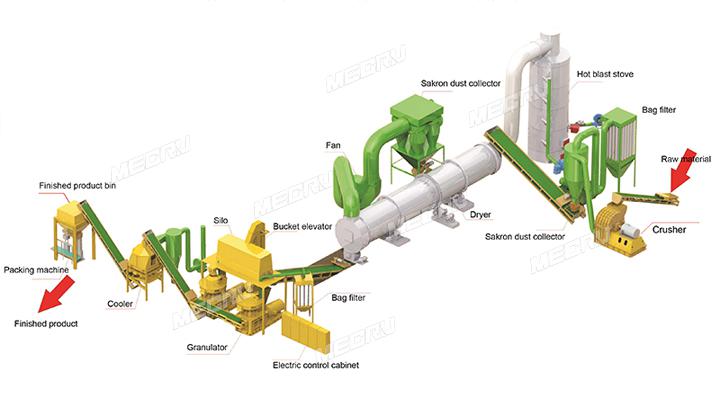

Calcined & grinding powder

- Mobile crushing plant Tracked Jaw Crusher Tracked Impact Crusher Tracked Cone Crusher Tyre Jaw Crusher Tyre Cone Crusher Tracked Screening Plant Tracked Heavy Screening Plant Multi-Combination Tyre Plant

- Stationary crushing plant Vibrating Feeder Gyratory Crusher C Series Jaw Crusher C Series Impact Crusher HPG Multi-cylinder Hydraulic Cone Crusher CG Single-cylinder Hydraulic Cone Crusher VSI Sand Making Machine Inclined Vibrating Screen Bucket Type Sand Washing Machine

- Mineral processing plant Ball Mill Cement ball mill YF Round Flotation Cell C Column Flotation Cell SF Square Flotation Cell Magnetic Separator Spiral Classifier Spiral Chute Shaking Table Trommel Screen High Frequency Vibrating Screen Agitating leaching tank Wet Pan Mill Centrifugal Gold Concentrator

- Hydrometallurgical plant Agitation Leaching (SX) Solvent Extraction (EW) Electrowinning EPC - Gold Cyanidation EPC - Copper Ore EPC - Copper-cobalt Ore

- Calcined & grinding powder Rotary Kiln Vertical Kiln Rotary Dryer Raymond Mill

+86 139 3711 5575

+86 139 3711 5575 mecru@mecru.com

mecru@mecru.com 8613937115575(Whatsapp/Wechat)

8613937115575(Whatsapp/Wechat) No. 67, Taojia Road, Guangwu Town, Xingyang City, Zhengzhou city, Henan Province, China

No. 67, Taojia Road, Guangwu Town, Xingyang City, Zhengzhou city, Henan Province, China